CONTACT CONSTRUCTION

Dear Customers - Investors!

Curb is an important construction item that many units are interested in. Curb is widely used to separate traffic, to transition between lanes, different road areas in industrial parks, residential areas.

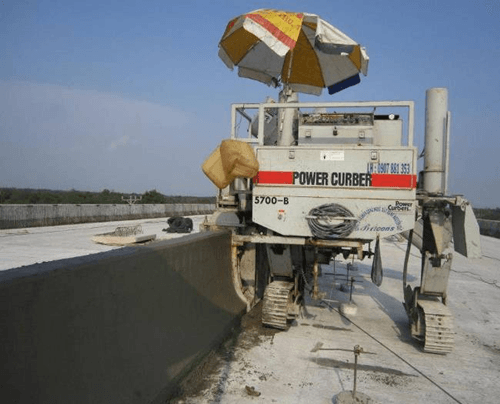

Manual curb construction in the past took a lot of time, effort, labor and was slow. To optimize the construction process, Nguyen Cat Investment - Construction Co., Ltd. has deployed the application of curb pouring with the POWER CURBER 5700 SUPER B curb forming machine and become a pioneer in curb construction with a spreader.

The method of curb construction by machine has many outstanding advantages:

- Through the implementation of construction, the machine demonstrates many superior features due to the use of a modern sensor system that makes curb pouring accurate and simple.

- The machine uses sliding mold technology to ensure uniform size and shape throughout the route.

- Continuously poured curbs help to connect well, prevent subsidence and ensure the aesthetics of the project.

- Thermal expansion joints are cut by machine, 3-5cm deep to ensure anti-cracking but still maintain the advantages of continuous concrete pouring technology.

- The machine can create different types of curbs depending on the design for each area.

- Concrete rammer technology helps curbs achieve high quality and durability.

- There is no cost for buying formwork boards, the cost is equal to the cost of normal labor but the construction time is only 15% compared to normal construction.

- The biggest advantage is that the machine has a very fast construction speed, averaging about 500m/day. If the capacity is increased to full capacity, it can be up to 1000m/day.

- In addition, we can issue value-added invoices for businesses to include in the cost.

Steps for pouring curbs using the POWER CURBER 5700 SUPER B curb forming machine

- Step 1: Place stakes, prepare the sensor wire

- Step 2: Send elevation and direction to the sensor wire

- Step 3: The curb is poured using the automatic sensor machine

- Step 4: Workers manually complete the curb surface.

We are pleased to receive all requests for quotations and consultation on all projects for pouring curbs and median strips using the American technology automatic machine POWER CURBER 5700 SUPER B.

NGUYEN CAT INVESTMENT-CONSTRUCTION COMPANY LIMITED

- Head office: 529/19 Nguyen Tri Phuong, Ward 8, District 10, Ho Chi Minh City, Vietnam.

- Branch 1: K37, Thoi An 1 Residential Area, Le Thi Rieng, Thoi An Ward, District 12, Ho Chi Minh City, Vietnam

- Branch 2: DT742, Bau Goc Hamlet, Binh My Commune, Tan Uyen District, Binh Duong Province, Vietnam

- Tel: (028) 62590496

- Fax: (028)62590493

- Email: nguyencatic@nguyencat.com.vn

- Website: www.nguyencat.com.vn

- In charge of curb construction: Mr.PHONG: 09.1819.3747

Completed Projects

-

03/08/2019

D20 ROAD - SHTP - HCM CITY

-

09/11/2023